Solutions | Compressed Air Consumption ...

Compressed air is a very important energy source in industry, but it can be enormously expensive. It is used in various applications such as the actuation and control of valves and pneumatic cylinders up to machining centres or individual instruments in production or the workshop. The air compression and distribution system consumes more electricity than any other equipment in the plant and for specific productions reaches up to 20% of a company's total energy cost calculation.

Monitoring compressed air consumption is therefore essential to identify any leaks or to understand where machines have been left in operation during the weekend or at the end of the shift. Or again to determine whether or not the installed compressors have a size that is appropriate to the various moments of consumption or if they are no longer all needed to run simultaneously and then be able to understand if it is possible to turn off one.

These control actions reduce the cost of electricity, reduce the environmental impact and extend the life of the compressor system equipment.

Obviously, when we talk about Compressed Air Consumption, we cannot ignore the most natural control we can have: an efficient and accurate Flow Measurement.

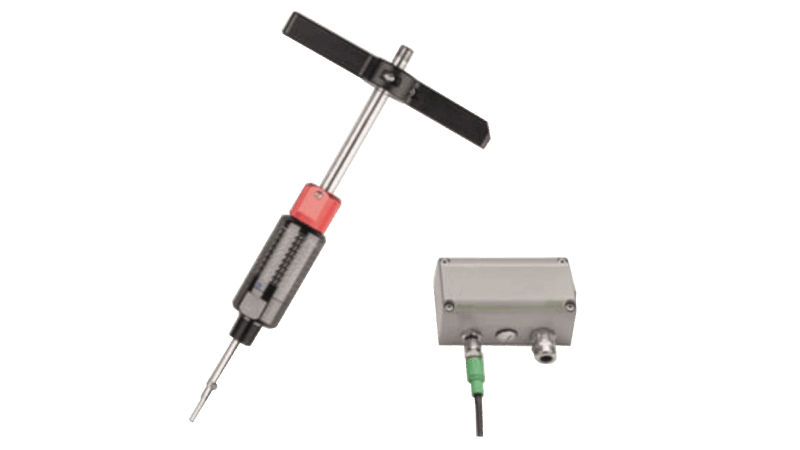

Kerberos offers solutions with insertion and in-line flow meters suitable for any type of plant that can be assembled and disassembled under pressure without interrupting the flow, in complete safety with non-return protection.

The KET-DMX-200 wireless module sends the data to the X-Monitor concentrator and makes it available in real time on the X-Platform Easy platform.

Do you want to optimize the monitoring of your business?

Discover our professional services that adapt to your needs and your business needs

contact us for a customized consultation