Solutions | Monitoring of Thermal Energ...

In order to obtain a profitable and efficient management of the energy requirements necessary for the heating/cooling or DHW cycles of the autonomous plants, it is essential to prepare an instrumental set that allows the collection of the fundamental data for the accounting of the physical heat. This allows not only to verify the accuracy of what is invoiced by the supplier, but also to make evaluations on the partialisation of the loads of the different thermal zones that make up the building.

By monitoring the flow and return temperatures of the plant circuit, with the aid of special temperature probes, and by accounting for the flow rate of the heat transfer fluid, the profile of the parameters necessary for calculating the thermal energy is traced over time.

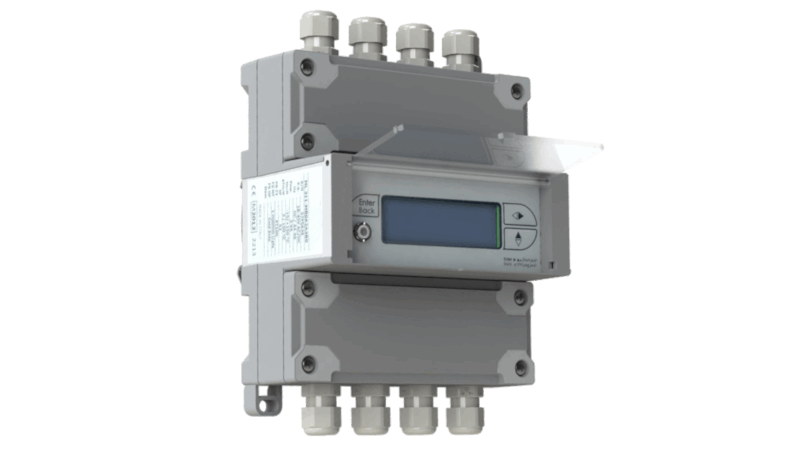

Kerberos offers a wide range of solutions for measuring and monitoring thermal energy, from the KET-SMR-100 with 2 temperature probes (flow/return) to kits of calorie/refrigeration meters of type electromagnetic or ultrasonic, either with direct insertion or clamp-on, each with an integrated thermal energy calculator.

The data sent to the X-Monitor concentrator are made available in real time on the X-Platform Easy platform.

Do you want to optimize the monitoring of your business?

Discover our professional services that adapt to your needs and your business needs

contact us for a customized consultation